AI and Aerodynamics at Insect Scale: MIT’s Bumblebee‑Sized Robot

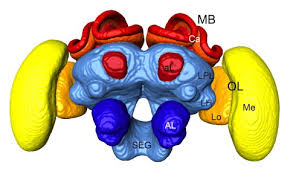

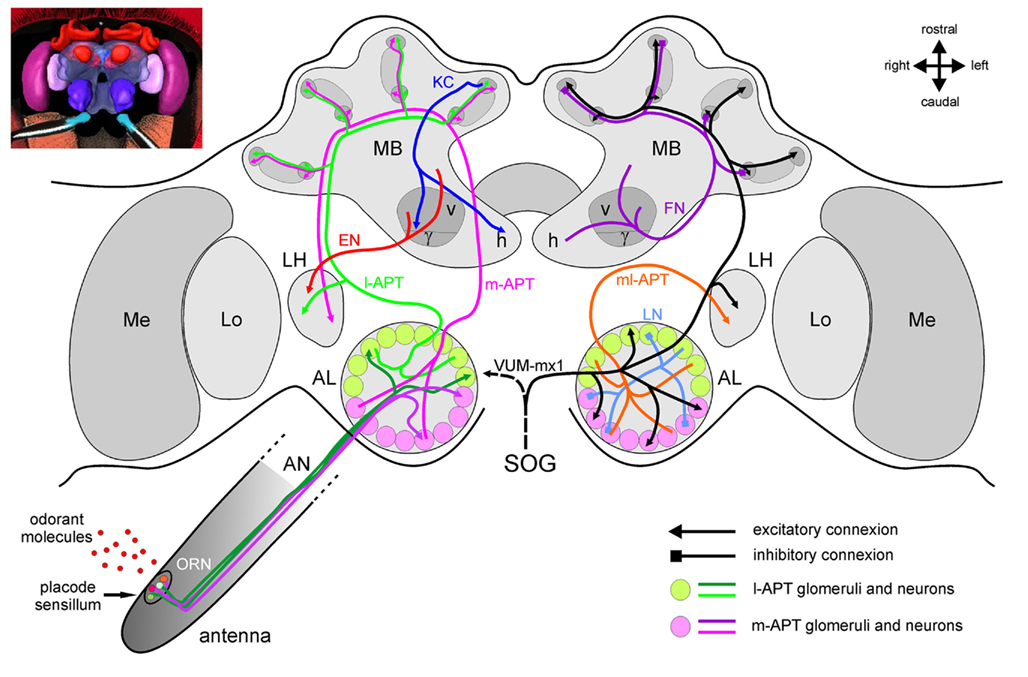

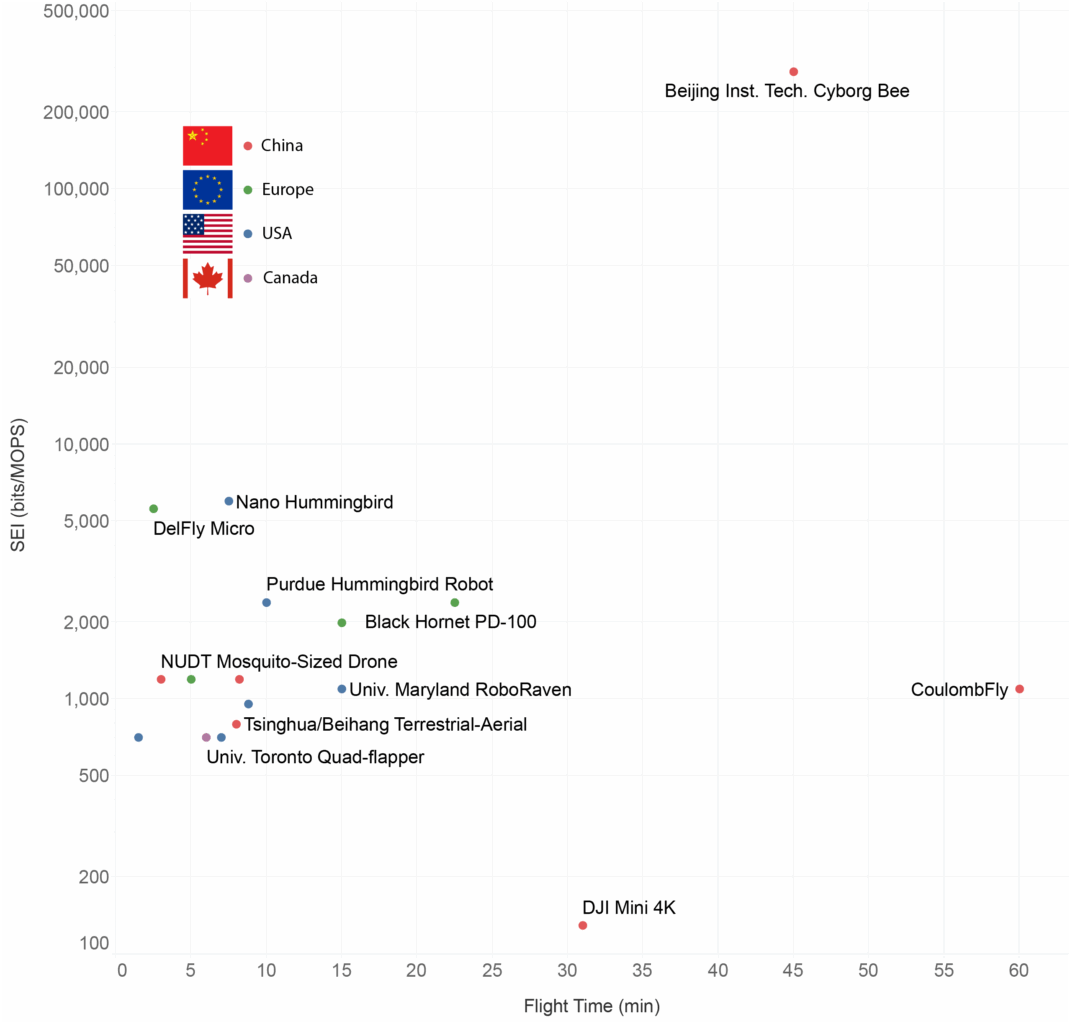

MIT soft robotics lab did an amazing job right at the intersection of physical systems, cyber and software. Small robots and insect-related autonomy have fascinated me for awhile. The autonomy of an insect brain is simple enough to just start to touch the boundaries of AI. The aero and mechanics of insects is still mind-bendingly ahead of our best planes (power, maneuver, agility, range).

MIT’s latest insect-scale robot fuses new soft “muscle” actuators, a redesigned four-wing airframe, and an AI-trained controller to achieve truly bug-like flight. Multi-layer dielectric elastomer actuators provide high power at much lower voltage, while long, hair-thin wing hinges and improved transmissions cut mechanical stress so the robot can hover for about 1,000 seconds and execute flips and sharp turns faster than previous microrobots. On top of that hardware, the team uses model-predictive control as an expert “teacher” and distills it into a lightweight neural policy, enabling bumblebee-class speed and agility in a package that weighs less than a paperclip and opens a realistic path to autonomous swarms for pollination and search-and-rescue.

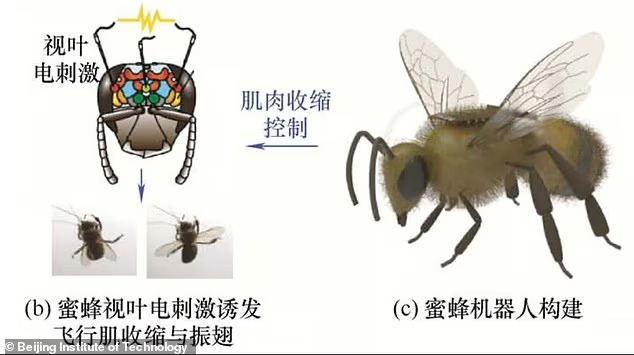

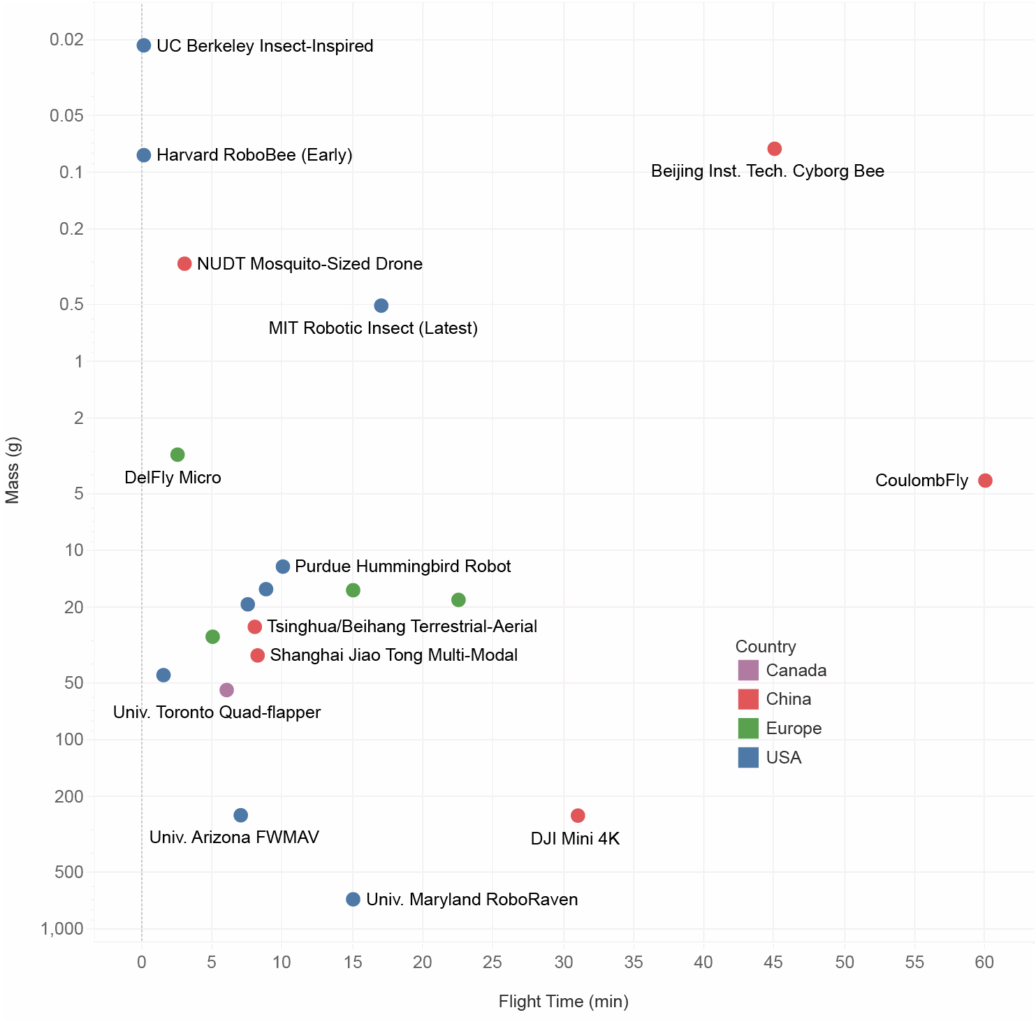

Tiny flying robots have long promised to help with tasks that are too dangerous or delicate for larger drones. Building such machines is extraordinarily difficult: the physics of flapping‑wing flight at insect scale and the constraints of small motors and batteries limit endurance and manoeuvrability. Over the past four years, engineers at the Massachusetts Institute of Technology (MIT) have made three major breakthroughs that together push insect‑scale flight from lab curiosity toward practical autonomy.

I built an animation using three.js to show just how cool this flight path can be.

The insect’s flight path is modeled using a discrete-time Langevin equation, which simulates Brownian motion with aerodynamic damping. At each time step \( t \), the velocity vector \( \mathbf{v} \) is updated by applying a stochastic acceleration \( \mathbf{a}_{\text{rand}} \) and a damping factor \( \gamma \) (representing air resistance):

$$ v_{t+1} = \gamma \, v_t + \mathbf{a}_{\text{rand}} $$

where \( \gamma = 0.95 \) and the components of \( \mathbf{a}_{\text{rand}} \) are drawn from a uniform distribution \( \mathcal{U}(-0.05, 0.05) \). The position \( \mathbf{p} \) is then integrated numerically:

$$ \mathbf{p}_{t+1} = \mathbf{p}_t + \mathbf{v}_{t+1} $$

This results in a “random walk” trajectory that is smoothed by the inertial momentum of the simulated robot, mimicking the erratic yet continuous flight dynamics of a small insect.

Flying robots smaller than a few grams operate in a very different aerodynamic regime from traditional drones. Their wings experience low Reynolds numbers where lift comes from unsteady vortex shedding rather than smooth airflow; getting useful thrust requires wings to flap hundreds of times per second with large stroke angles. At such high frequencies, actuators often buckle and joints fatigue. The robots have extremely tight power and mass budgets, making it hard to carry batteries or onboard processors. Early insect‑like microrobots could just barely hover for a few seconds and needed bulky external power supplies.

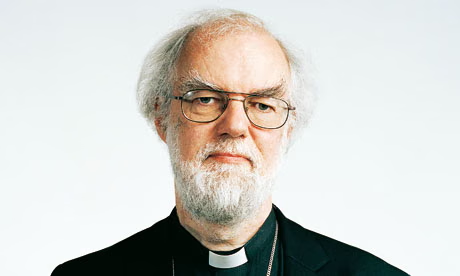

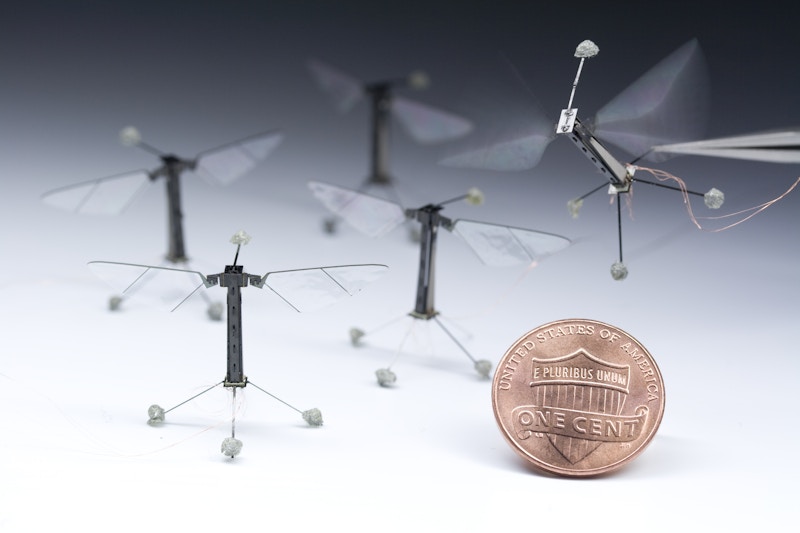

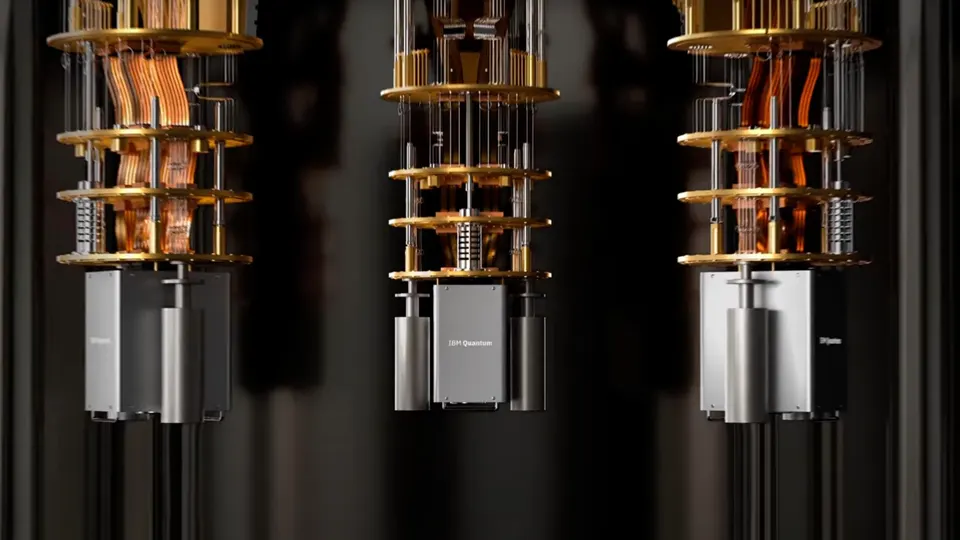

Credit: Courtesy of the Soft and Micro Robotics Laboratory

MIT’s Soft and Micro Robotics Laboratory, led by Kevin Chen, set out to tackle these problems with a combination of novel soft actuators, mechanically resilient airframes and advanced control algorithms. The resulting platform evolved in three stages: improved artificial muscles (2021), a four‑wing cross‑shaped airframe with durable hinges and transmissions (January 2025) and a learning‑based controller that matches insect agility (December 2025).

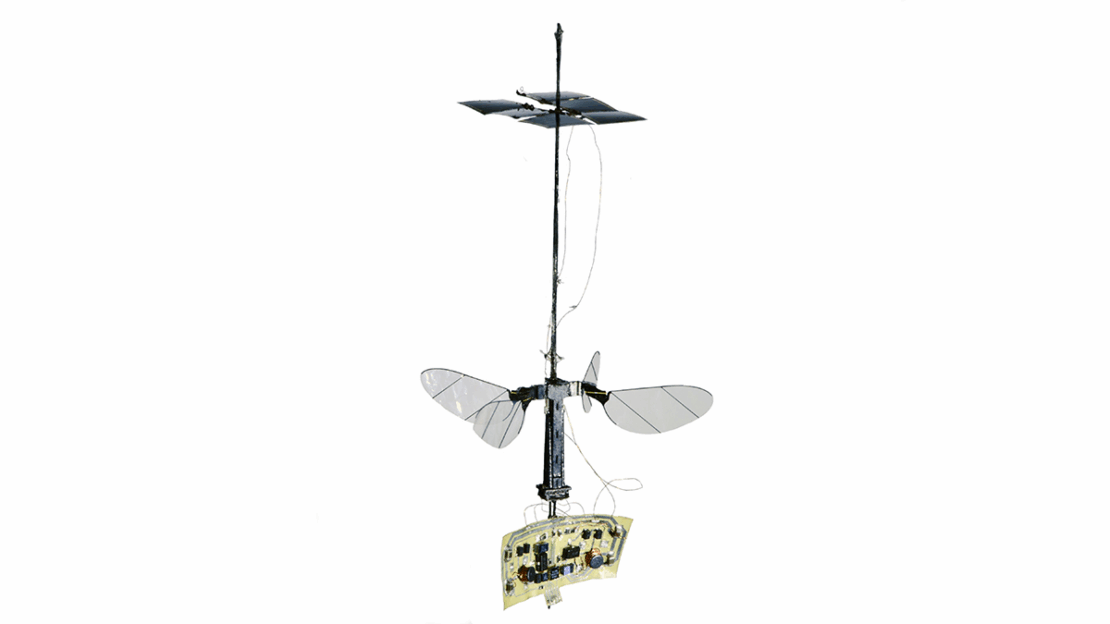

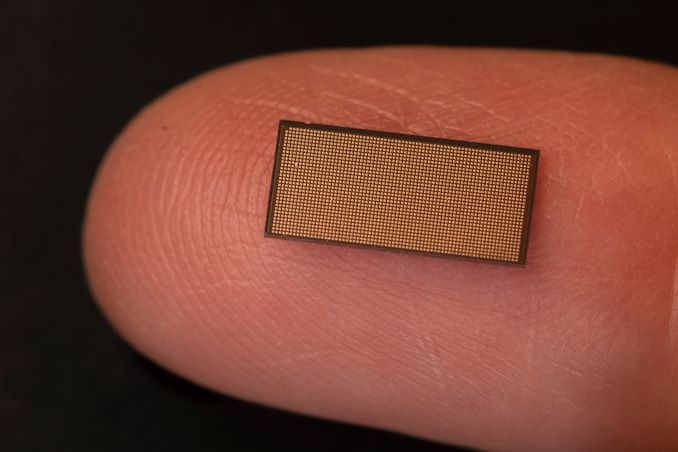

The first breakthrough addressed the “muscle” problem. Conventional rigid actuators were too heavy and inefficient for gram‑scale robots. Chen’s group developed multilayer dielectric elastomer actuators—soft “muscles” made from ultrathin elastomer films sandwiched between carbon‑nanotube electrodes and rolled into cylinders. In 2021 they unveiled a fabrication method that eliminates microscopic air bubbles in the elastomer by vacuuming each layer after spin‑coating and baking it immediately. This allowed them to stack 20 alternating layers, each about 10 µm thick , without defects.

Key results from this work included:

- Lower voltage and more payload: The new actuators operate at 75% lower voltage and carry 80% more payload than earlier soft actuators. By increasing surface area with more layers, they require less than 500V to actuate yet can lift nearly three times their own weight.

- Higher power density and durability: Removing defects increases power output by more than 300% and extends lifespan. The 20‑layer actuators survived more than 2 million cycles while still flying smoothly.

- Record hovering: Robots powered by these actuators achieved a 20‑second hovering flight, the longest yet recorded for a sub‑gram robot. With a lift‑to‑weight ratio of about 3.7:1, they could carry additional electronics.

The low‑voltage soft muscles solved a critical bottleneck: the robots could now carry lightweight power electronics and eventually microprocessors instead of being tethered to an external power supply. This breakthrough laid the hardware foundation for future autonomy.

Aerodynamic and structural redesign: four wings, durable hinges and long endurance

The second breakthrough came in early 2025 with a redesign of the robot’s wings and transmission. Previous generations assembled four two‑wing modules into a rectangle, creating eight wings whose wakes interfered with each other and limiting control authority. The new design arranges four single‑wing units in a cross. Each wing flaps outward, reducing aerodynamic interference and freeing up central volume for batteries and sensors.

To exploit the power of the improved actuators, Chen’s team built more complex transmissions that connect each actuator to its wing. These transmissions prevent the artificial muscles from buckling at high flapping frequencies, reducing mechanical strain and allowing higher torque. They also developed a 2 cm‑long wing hinge with a diameter of just 200 µm, fabricated via a multistep laser‑cutting process. The long hinge reduces torsional stress during flapping and increases durability; even slight misalignment during fabrication could affect the wing’s motion.

Performance improvements from this structural redesign were dramatic:

- Extended flight time: The robot can hover for more than 1,000 seconds (~17 minutes) without degradation of precision —100 times longer than earlier insect‑scale robots.

- Increased speed and agility: It reaches an average speed of 35 cm/s and performs body rolls and double flips. It can precisely follow complex paths, including spelling “MIT” in mid‑air.

- Greater control torque: The new transmissions generate about three times more torque than prior designs , enabling sophisticated and accurate path‑following flights.

These mechanical innovations show how aerodynamic design, materials engineering and manufacturing precision are intertwined. By reducing strain on the wings and actuators, the platform gains not only endurance but also the stability needed for advanced control.

Autonomy, AI and Systems Engineering

The final breakthrough is in control theory as it intersects autonomy. Insect‑scale flight demands rapid decision‑making: the wings beat hundreds of times per second, and disturbances like gusts can quickly destabilize the robot. Traditional hand‑tuned controllers cannot handle aggressive maneuvers or unexpected perturbations. MIT’s team collaborated with Jonathan How’s Aerospace Controls Laboratory to develop a two‑step AI‑based control scheme.

Step 1: Model‑predictive control (MPC). The researchers built a high‑fidelity dynamic model of the robot’s mechanics and aerodynamics. An MPC uses this model to plan an optimal sequence of control inputs that follow a desired trajectory while respecting force and torque limits. The planner can design difficult maneuvers such as repeated flips and aggressive turns but is too computationally intensive to run on the robot in real time.

Step 2: Imitation‑learned policy. To bridge the gap between high‑end planning and onboard execution, the team generated training data by having the MPC perform many trajectories and perturbations. They then trained a deep neural network policy via imitation learning to map the robot’s state directly to control commands. This policy effectively compresses the MPC’s intelligence into a lightweight model that can run fast enough for real‑time control.

The results show how AI enables insect‑like agility:

- Speed and acceleration: The learning‑based controller allows the robot to fly 447% faster and achieve a 255% increase in acceleration compared with their previous best hand‑tuned controller.

- Complex maneuvers: The robot executed 10 somersaults in 11 seconds, staying within about 4–5 cm of the planned trajectory and maintaining performance despite wind gusts of more than 1 m/s

- Bio‑inspired saccades: The policy enabled saccadic flight behavior, where the robot rapidly pitches forward to accelerate and then back to decelerate, mimicking insect eye stabilization strategies.

An external motion‑capture system currently provides state estimation, and the controller runs offboard. However, because the neural policy is much less computationally demanding than full MPC, the authors argue that similar policies may be feasible on tiny onboard processors. The AI control thus paves the way for autonomous flight without external assistance.

A key message of MIT’s microrobot program is that agility at insect scale does not come from a single innovation. The soft actuators enable large strokes at lower voltage; the cross‑shaped airframe and long hinges reduce mechanical strain and aerodynamic interference; and the AI‑driven controller exploits the robot’s physical capabilities while respecting constraints. Chen’s group emphasizes that hardware advances pushed them to develop better controllers, and improved controllers made it worthwhile to refine the hardware.

This co‑design philosophy—optimizing materials, mechanisms and algorithms together—will be essential as researchers push toward untethered, autonomous swarms. The team plans to integrate miniature batteries and sensors into the central cavity freed by the four‑wing design, allowing the robots to navigate without a motion‑capture system. Future work includes landing and take‑off from flowers for mechanical pollination and coordinated flight to avoid collisions and operate in groups. There are also open questions about enabling onboard perception—using tiny cameras or event sensors to close the loop—and about energy management to extend endurance beyond 10,000s.

MIT’s bumblebee‑sized flapping robot illustrates how progress in materials science, precision fabrication, aerodynamics and AI can converge to solve a hard problem. The low‑voltage, power‑dense actuators prove that soft materials can outperform rigid designs, the four‑wing airframe with durable hinges unlocks long endurance and high torque, and the hybrid MPC/learning controller shows that sophisticated planning can be compressed into hardware‑friendly neural policies. Together, these advances give the microrobot insect‑like speed, agility and endurance.

While still reliant on external power and motion capture, the robot’s modular design and AI controller suggest a roadmap to fully autonomous operation. As the team integrates onboard sensors and batteries, insect‑scale robots could move from labs to fields and disaster zones, pollinating crops or searching collapsed buildings. In that future, the intersection of autonomy and aerodynamics will be defined not by a single breakthrough but by a careful co‑design of muscles, wings and brains.